One of the world’s leading model railway manufacturers, PECO, has just taken receipt of a Sodick ALC400G ‘iGroove edition’ wire-erosion machine – one of only four in the UK, and to add to its stable of three other Sodick machines at its site in Beer, Devon.

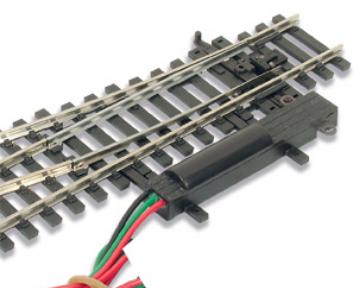

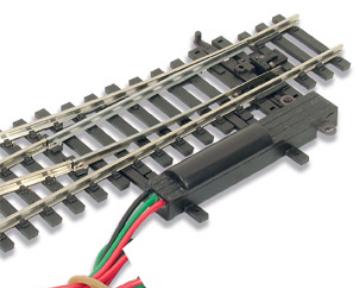

The move by PECO to invest in this new state-of-the-art machine, will enable the company to create mould and press tools, as well as jigs and fixtures to an accuracy of within 1/100th of a millimeter, eliminating the need for form-grinding and maximising the accuracy of its tools, which it uses to make the highest quality and precision model railway track and accessories.

The PECO toolroom currently has around 1600 mould and press tools, jigs and fixtures available for use, mostly made from high-grade tool steel.

PECO Innovations Manager Paul Hitchcock comments "When we make a new product it rarely drops out of our catalogue, so it’s always there for customers if needed. We have a few mould tools that are around 40 years old, although they are subject to scheduled refurbishment using our Sodick wire EDM, to ensure continuous product quality.”

EDM (Electro Discharge Machining) wire erosion is a precision-engineering process where hardened steel can be accurately cut with a micron wire, by creating electrical sparks between the wire and the work-piece. The sparks are tightly controlled, and to make sure that the cutting is as accurate as possible, dielectric de-ionised water is used. The water acts as a coolant to ensure the metal components do not overheat and to flush away any particles created by the electrical erosion process.

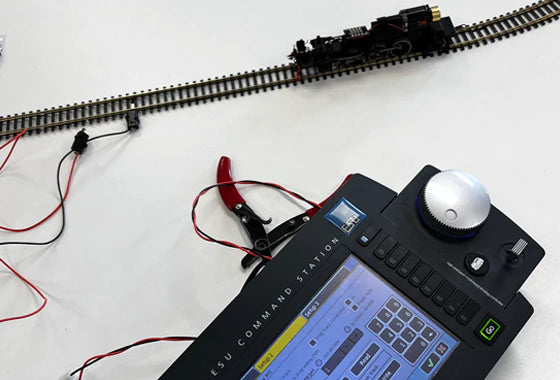

Established in 1946, PECO (Pritchard Patent Product Co Ltd) has its headquarters and manufacturing plant in the picturesque Devon fishing village of Beer, where the 150-employee business produces model rolling stock and track across eight different scales (from Z to G), as well as lineside/scenic and electrical accessories. Manufacturing in-house is clearly important to this progressive business, which is why the company runs a fully equipped toolroom.

The company is also heavily investing in the expansion of its workforce and is currently looking to recruit new engineers and apprentices, to operate their latest machinery such as the Sodick ALC400G.